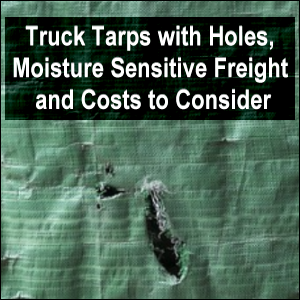

Every trucker using truck tarps with holes to cover flatbed loads of moisture sensitive freight needs to understand that there are costs that can affect profitability.

Let us explain.

Let us explain.

Freight to be Tarped

Imagine for a moment that on his or her flatbed, there are three different kinds of products which may be subject to rain or road spray:

- those which can get wet without being damaged;

- those which may be damaged and which the customer may reject; and

- those which cannot get wet (or even damp) and which the customer will reject.

Among the types of product that cannot get wet are sheet rock (dry wall) and insulation.

What happens if in spite of the need to keep products dry, truck tarps with holes are used to “cover” the load?

Putting Things in Perspective

Let’s further imagine that a driver takes a load covered with tarps with holes in rain (or even road spray) to a customer.

Let’s further imagine that a driver takes a load covered with tarps with holes in rain (or even road spray) to a customer.

If the products on board have gotten damp (or downright wet) and potentially damaged, the customer has every right to refuse that part of the load.

Assume that the driver delivering the products has a local truck driving job.

When product under tarps with holes has been refused, let’s suppose that the driver has to take that part of the load back to his company’s terminal.

Depending on the extent of the damage, the affected part of the load always incurs some kind of loss by having to be:

- thrown away,

- sold as second quality goods or

- re-delivered later (if it can be, after it has dried out).

Why is loss incurred from re-delivering it later?

We’re glad you asked!

The Cost of Re-Delivering Freight

Let’s assume that the part of the load that the customer rejected — because of tarps with holes — takes up just 15% of the space on the trailer and/or weight of the whole load.

Let’s assume that the part of the load that the customer rejected — because of tarps with holes — takes up just 15% of the space on the trailer and/or weight of the whole load.

If the driver was planning to make a pick-up after delivering his/her product, that much less space/weight is available for a new load.

Furthermore, if that part of the load can be delivered later, it will have taken twice the amount of

- time or

- miles or

- both

to be delivered.

In this case, there may be a loss to the trucking company but not a company driver.

Truckers who are paid on a percentage of the load come out on the losing end.

Regular Tarp Inspections, Repairs or Replacement

It would be far better for trucking companies to regularly inspect their tools and equipment for tarps with holes.

It would be far better for trucking companies to regularly inspect their tools and equipment for tarps with holes.

In this way, they can find out where loss is occurring.

Questions to ask include:

- How many times must parts of loads be rejected by customers before it costs more that the cost of repairing or replacing tarps?

- Can all truck tarps be repaired?

- How much work is it to repair tarps?

- Are truckers instructed on how to repair tarps or should this work be done by others?

If a Damaged Load is Delivered Once…

Not only must the raw numbers be taken into account regarding tarps with holes, but if a customer has been offered potentially damaged freight once, he or she is going to be especially wary of future loads delivered in damp or wet conditions.

Not only must the raw numbers be taken into account regarding tarps with holes, but if a customer has been offered potentially damaged freight once, he or she is going to be especially wary of future loads delivered in damp or wet conditions.

You don’t want to damage your reputation for delivering high quality products by neglecting maintenance or replacement of truck tarps with holes.

A real point of contention occurs when drivers are held responsible for protecting their loads from rain and road spray, but when the tools they are given with which to do it are in inferior condition.

Using tarps with holes to cover freight would be like you going out in the rain with holes in your umbrella!

Truckers whose jobs are on the line if they don’t protect their loads are especially vulnerable.

Don’t Make Your Drivers Beg

It’s pretty sad when truckers driving for trucking companies that are supposed to be profit-driven keep their drivers in a conflicted position.

It’s pretty sad when truckers driving for trucking companies that are supposed to be profit-driven keep their drivers in a conflicted position.

Truckers shouldn’t have to beg for the tools and equipment to do their jobs.

Tarps with holes should be repaired or replaced!

Still, every once in a while, a trucker has to point out the obvious to someone in a position of authority.

The following is a trucker’s email (which has been edited only enough to remove personally identifiable information).

| Good morning [supervisor’s first name].

The tarping issue may seem like the big issue, but it’s not. It’s really secondary to this: LOSS. Please allow me to explain. Whenever freight is taken to a customer and is rejected for whatever reason, that’s loss. In our case, weather plays a major factor with much of our commodity. And when it gets wet, the customer has the right to say no. That’s loss to our company because it has to be brought back, incurring miles and time. Then the company has to reschedule delivery of that product, paying for a drop and the miles to get it there. If the truth were told, damaged freight can no longer be sold as first quality. That’s loss! The company has paid full cost for first quality but has to sell at a discount for some willing buyer. That’s loss! And when there’s enough loss to a company, all is far from well. Our customers get frustrated when they receive less than first quality. They can exercise the option of finding a new vendor who will deliver better quality freight, and they will, given the opportunity. Declining revenues are never good for anybody. That’s loss. For 3 years now, I’ve truly sought to learn this business and do an excellent job for my customers. I want them to know and have told them that I do the very best for them that I can. They sincerely appreciate that! But it goes completely contrary to my work ethic to say that I just don’t care any more. I’ve begged and pleaded for good tools to do my job, and for my coworkers as well. But if the powers that be are content to let weather sensitive freight be returned due to road spray or rain because I’ve not been given the best tools, there’s nothing more I can do. I’m weary with begging and pleading. And should it be the case that other drivers are brought in, the problem still exists whether my coworkers and I are here or not. Yes, we must have good tarps! We’ve asked for them and our requests have seemed to fall on deaf ears. Right now, I have one tarp that barely covers part of my load. It’s been cut short and there’s just no way a double stack could be covered with it. I saw a purchase order just 2 days ago that totalled over $4000. Is it too much to ask that $3000 of that be earmarked for brand new, light weight durable lumber tarps for our yard? Apparently somebody thinks it is. I’m appealing to you as my direct supervisor to kick this as far up the ladder as it needs to go in order for our respective companies to not have to suffer loss from inadequately tarped product being rejected by our long-time customers. I see them 5 days a week. I’m there seeing their faces and interacting with them when making deliveries. If nothing more, we must keep them happy so they can serve their customers well too. I don’t want them to suffer loss either! Frankly, I’m unconcerned about who reads this. But my hope is that this epistle spurs immediate action by whomever has authority to make the decision to get us drivers what we must have that has been lacking for so long. You have information that was sent in a recent email that can still prove helpful. Thanks for reading. Sincerely, [driver’s full name] |

![]() Money saving tip: Regularly inspect the tarps you use on your truck. If there is a hole, it is best to repair it when it is small.

Money saving tip: Regularly inspect the tarps you use on your truck. If there is a hole, it is best to repair it when it is small.

The life expectancy of a tarp depends on many factors.

It is better to replace tarps with holes than run the risk of attempting to deliver product in an unacceptable condition. Mentally, put yourself in your customer’s shoes and see how it feels to be offered damp or wet moisture-sensitive products.

Professional truck drivers who know that the tarps assigned to their truck have holes in them, need to report them to their company.

If the need for new tarps has been made known — but none are provided — it is time to document with photos exactly what they are up against.

If necessary, invest in a moisture meter to measure the moisture content in your product several times to prove your point.

Protect yourself!

Can part of your load be covered “under” the tarp with a type of bag?

If so, investigate the possibility of using that kind of product.

Every time a trucker has to climb up on a flatbed trailer in order to tarp a load, he or she runs the risk of falling off the trailer.

Some truckers wear devices attached to an overhead system to help them avoid falls. These devices are generally stationary at a location, not moving with the truck.

Although it has a steeper upfront cost, an automatic tarping system has been said to pay for itself quickly.

Return from Truck Tarps with Holes, Moisture Sensitive Freight and Costs to Consider to our Tools and Equipment page or our Truck Drivers Money Saving Tips home page.