Does the fifth wheel — which has been defined as “the coupling table of an articulated vehicle” — on your tractor need to be moved? Is it “stuck” after months or years of use?

Consider using our tips before you make a service or breakdown call…

Consider using our tips before you make a service or breakdown call…

This is a photo of a 5th wheel platform on a brand new tractor, never before used or moved.

You can clearly see the many slots or holes into which the mechanism’s pins can be fitted.

You can clearly see the many slots or holes into which the mechanism’s pins can be fitted.

In the close-up view, you can see the pins fitted into the two most rearward holes on the tractor.

In the close-up view, you can see the pins fitted into the two most rearward holes on the tractor.

Obviously, there is little road dirt and no platform grease.

This is the entire release assembly from the air hose valve on the left to the spring-loaded release on the right.

This is the entire release assembly from the air hose valve on the left to the spring-loaded release on the right.

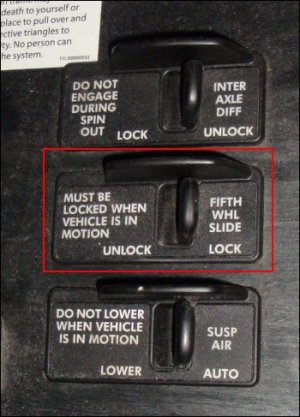

This assembly works in conjunction with the “fifth wheel slide” lever on the dash inside the tractor, which you see inside the red box in this photo.

This assembly works in conjunction with the “fifth wheel slide” lever on the dash inside the tractor, which you see inside the red box in this photo.

This is where the lever is on the dash of the Freightliner Columbia that Mike drove for his trucking company.

The lever as shown is in the “locked” position, meaning that the pins are through the holes.

If Mike wanted to move the platform, he would move the lever to the “unlock” position.

The directions on the dash state, “Must be locked when vehicle is in motion.”

Mike’s many years of experience in driving an 18-wheel tractor trailer has taught him that the platform must be moved when there is too much weight on the drive axles when scaling out.

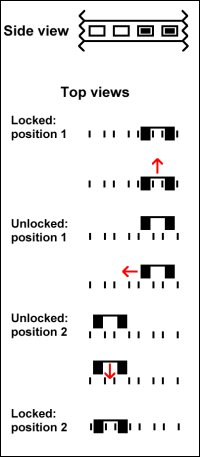

This illustration is our best attempt to show what happens when a fifth wheel platform is moved.

This illustration is our best attempt to show what happens when a fifth wheel platform is moved.

The eight cutaway views are the “view” from the side and 7 “views” from the “top.”

First, the pins are locked in position 1.

The fifth wheel slide lever is moved from lock to unlock to pop the pins out of position 1 holes.

The driver works to move the fifth wheel on the slide.

When the pins are in the new position (position 2), the fifth wheel slide lever is moved from unlock back to lock.

At this point, the pins are locked in position 2.

Unlike trailer tandems which are moved often, the fifth wheel platform on a tractor trailer is not generally moved once it is originally set by the first driver.

The weight distribution per hole of the fifth wheel platform may vary depending on the tractor-trailer combination. Please note that the fifth wheel setting is independent of both the king pin and trailer tandem settings.

This photo shows the platform under a trailer and where the pins are positioned along the slide.

This photo shows the platform under a trailer and where the pins are positioned along the slide.

You can see that the mechanism has a healthy coating of road dirt and platform grease.

This close-up photo shows that the two pins are in the most forward position along the slide on Mike’s tractor.

This close-up photo shows that the two pins are in the most forward position along the slide on Mike’s tractor.

This position may or may not be right for your tractor-trailer combination.

Helpful Tips

The following information is made available as the voice of experience and is not to be construed as advice.

The following information is made available as the voice of experience and is not to be construed as advice.

Your trucking company, the manufacturer of your tractor and/or the manufacturer of the trailer you are hauling may recommend a different procedure for moving a stuck fifth wheel platform.

However, this may come in handy if you are sure that the only means of making your load legal is to move this mechanism and the only other thing left to do is to make a service call or call “breakdown.”

If you find that you need to move your 5th wheel platform and you have a sliding lever in your tractor, first make sure that your tractor is under a trailer (preferably loaded).

Set your trailer brake.

Then, assuming that your tractor has one, move the fifth wheel slide lever on your dash from “lock” to “unlock.”

Move your tractor so that the mechanism’s pins go to where you want them to be.

If you have difficulty getting the pins to retract, try gently rocking your tractor back and forth to see if you can dislodge them.

If rocking your tractor does not work to remove the pins from the holes, try squirting some soapy water onto the pins and the holes where they are stuck.

(Obviously, don’t use water when it’s freezing outside.)

Some people prefer using a lubricant (like the one shown here) to help dislodge the pins.

Repeat the gentle rocking to see if that action works to retract the pins.

If there is too much pressure from the load in the trailer on the platform, this can impede the sliding process.

So, to remove some of this weight, you may want to temporarily lower the landing gear on your trailer.

If you need to do this, putting your trailer down on a concrete pad is preferable to any other kind of surface.

If the soapy water and lowering of trailer landing gear does not work to help you move the mechanism’s pins, try gently tapping the pins with a hammer.

This may loosen the road dirt and old platform grease enough to loosen the pins.

If the hammer approach does not work, try squirting a little WD-40 or Penetrating Blaster on the pins.

You may buy WD-40 through Amazon.com, with whom we have an affiliate relationship.

(Vicki prefers WD-40 because she doesn’t like the smell of PB. But both work well on dislodging stuck things.)

Let the lubricant “soak in” for a couple of minutes to work its way into the gunk.

Bear in mind that the lubricant is not supposed to interfere with any other moving parts on the tractor or trailer, nor is it a substitute for platform grease.

Hopefully, between the unlocked lever, movement of the tractor, the soapy water, the landing gear lowering, the hammer tapping and the lubricant application, you will be able to loosen the pins on the fifth wheel platform and slide it to the desired location.

![]() Money saving tip: While we have never had to make a service call for this kind of mechanical need, every service call is expensive.

Money saving tip: While we have never had to make a service call for this kind of mechanical need, every service call is expensive.

Generally, you will be paying the service technician or mechanic an hourly rate, plus mileage, plus any supplies that he must furnish to get your rig’s setting where it needs to be.

Additional charges may also apply.

Save yourself the expense by doing the dislodging work yourself.

If you need help, most professional drivers are willing to assist you.

Return from Moving the Fifth Wheel on Your 18-Wheel Tractor Trailer to our Tricks of the Trade page or our Truck Drivers Money Saving Tips home page.