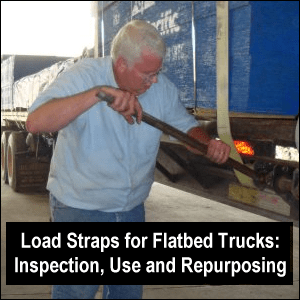

When Mike got a local truck driving job pulling a flatbed, load straps became very important to him.

He had no need to be concerned about them when he hauled dry vans, refrigerated vans or tankers.

He had no need to be concerned about them when he hauled dry vans, refrigerated vans or tankers.

But since these items — or chains — are used to hold freight securely on a flatbed while it’s in transit, it is important to inspect them and use them correctly.

Not only that, but we’ll share how even damaged straps can be repurposed.

Load Straps Photo Gallery

Mike surveys the flatbed load, where straps have to be placed for flatbed load securement.

Mike surveys the flatbed load, where straps have to be placed for flatbed load securement.

He is winding the strap that he’s pulled off the winch, so that he can throw it over the top.

Mike pulls a strap off the winch.

Mike pulls a strap off the winch.

As he does so, he is able to inspect it for holes, frayed edges or other signs of distress.

Unless the load is tarped (usually only in bad weather), the straps bear the brunt of weather and road dirt.

They are also tightened down.

Mike is getting ready to throw a load strap over the freight.

Mike is getting ready to throw a load strap over the freight.

Heights of bundles of freight may vary.

Each strap must be positioned where it will hold the freight securely in place.

Each flatbed load required on average about 10 of the 12 load straps.

At times, he used all 12 straps.

This strap has been pulled off the winch and is waiting to be

This strap has been pulled off the winch and is waiting to be

– wound,

– thrown over the top,

– connected on the other side and

– then tightened.

In such an exposed view, one can easily find during an inspection any

– holes,

– frayed edges or

– other signs of distress.

Mike cinches down a strap with a “breaker bar.”

Mike cinches down a strap with a “breaker bar.”

It requires quite a bit of physical strength to tighten these down on a flatbed.

One must be careful to guard against potential injuries when tightening load straps.

One must be careful to guard against potential injuries when tightening load straps.

Here, Mike is in the “downward” position as he has rotated the winch to tighten the strap.

Mike inserts the breaker bar’s end into the winch in order to tighten the strap.

Mike inserts the breaker bar’s end into the winch in order to tighten the strap.

Repurposing Old Straps

At left is a collage of illustrations of how to repurpose an old strap for continued use on a flatbed load:

At left is a collage of illustrations of how to repurpose an old strap for continued use on a flatbed load:

– take an undamaged piece of strap (no holes, frayed edges, etc.) and

– attach it to two runners in order to use it as a corner protector.

This has limited applications.

In the side view, the runners can be on top of or underneath the strap on the load, depending on need.

In the top view, the straps are attached to the runners at or near the ends.

![]() Money saving tip: Buy the type of load straps that are rated for the type of load you will be hauling.

Money saving tip: Buy the type of load straps that are rated for the type of load you will be hauling.

The type of strap Mike used is rated to hold 5400 pounds.

You may require heavier or lighter straps, or more or fewer straps, depending on your load.

Protect your breaker bar; without it, you will not be able to tighten your straps on the winches.

Follow your company’s procedure on how to tighten straps without hurting yourself (especially your back).

To strengthen yourself, do appropriate physical exercises.

Beware of losing your grip on your breaker bar when you are “between teeth” on the winch.

It could snap back and hit you.

Repurpose old straps with runners as homemade corner protectors in limited applications.

Be sure to use the type of corner protectors required by your customer or company or both.

When throwing your load straps over the top of a load, make sure that you have adequate clearance on both sides of your truck.

You don’t want to hit anything or anyone when throwing it (on either side of the truck).

Mike says one of two things when he’s getting ready to throw a strap over the top when he knows people are around: “Watch your head!” or “Coming over!”

When he worked at this workplace, one of his co-workers who is in the area usually responded: “Go ahead!”

Of course, Mike prefers to strap down his load when nothing and no one else is around.

Return from Load Straps for Flatbed Trucks: Inspection, Use and Repurposing to our Tools and Equipment page or our Truck Drivers Money Saving Tips home page.